Troubleshooting Steps in Mobile Repairing

Regardless of how your particular smartphone might be, a dependable Troubleshooting Steps in Mobile Repairing can be broken down into four basic steps.

#Step 1: Define Your Symptoms

#Step 2: Identify and isolate the location of your problem

#Step 3: Replace the suspected component, and

#Step 4: Re-test the component thoroughly to be sure that you have solved the problem. If not solved the problem, start from Step #1.

This is the Universal procedure that you need to be applied in the general troubleshooting steps in mobile repairing.

Define Your Symptoms

When a phone breaks down, the cause might be a simple as a loose wire or a connector or a complicated as an IC or component failure. Before you start, you must have a good understanding of all the symptoms, it can be much easier to trace a problem to the appropriate component. Take the time to write down as many symptoms as you can. As a technician, you must often write problems and solutions for reference purposes.

Identify and Isolate

Before you try to isolate a problem within a piece of hardware, you must first be sure that the equipment itself is causing the problem. In many cases, this will be fairly obvious, but some situations might not be. A faulty or improperly configured piece of software can cause confusing system errors. When you are sure that it is a system’s hardware failure, you can begin to identify which component fails.

Replace

Because phones are designed as a sub-unit, it is almost always easier to replace a sub-unit outright, rather than attempt to repair the sub-unit to its component level. Even if you had the time to isolate the defective component, many parts are not interchangeable. So it is better to replace the defective part than try to repair it.

Re-test

When a repair is finally complete, the system must be reassembled carefully before testing it. All guards, housing, cables, and shields must be placed before final testing. If symptoms persist, you will have to reevaluate the symptoms and narrow the problem to other parts of the equipment. When you can verify that the symptoms have stopped during the actual operation, the equipment can be returned to service. As a general rule, it is wise to let the system run for at least hours to ensure that the replacement sub-assembly will not fail prematurely.

Do not be discouraged if the equipment still malfunction. Maybe software settings and device drivers may need to be updated. If you are tired simply walk away, clear your hand and start again by defining the current symptoms. Never continue with a repair if you are tired or frustrated, tomorrow is another day. Even the most experienced troubleshooters get overwhelmed from time to time.

Now we shall see the basic methods of the fault-finding process or troubleshooting steps in Mobile Repairing

Troubleshooting Steps in Mobile Repairing

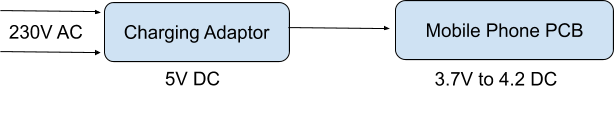

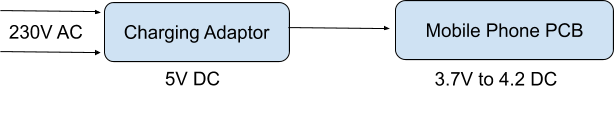

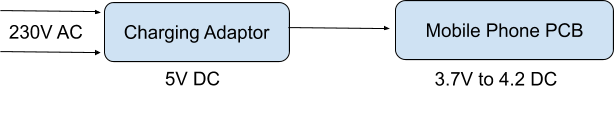

Mobile Operating Voltage

It is very important to know the operating voltage of a mobile phone. Kindly take note of it as it is the first step of the diagnosis of any mobile phone for fault. The Mobile Battery Voltage (MBV) should be between 3.7V to 4.2V. If the battery is below the given range, the mobile phone will not operate. In this scenario, you need to boost the battery through DC Power Supply or Battery Booster so that it reaches above 3.7V.

Mobile Phone Diagnosis | Testing Methods

There are two methods that you can use to find out faulty or damaged components on a mobile phone. These are:

- Cold Testing Method

- Hot Testing Method

Troubleshooting Steps in Mobile Repairing | Cold Testing Method

Cold Testing Method:

Cold testing is when we use a multimeter to check the value of resistance at the time of repairing a fault in a mobile phone. During cold testing do not power the phone from any equipment. Use the diode range and beep sound from the multimeter to find fault in the mobile phone.

During cold testing, you should connect the RED probe of the multimeter to the ground of the mobile phone PCB, and use the BLACK probe to touch the testing points of the mobile phone. During the fault-finding and repairing process of each part, component, or section, you should receive the following correct values:

- Earphone Connector Tip (+ , -): 500~700 Ohm

- Loud Speaker / Ringer Connector Tip (+,-): 300~600 Ohm

- Battery Connector Tip (+): 250~600 Ohm

- Battery Connector Tip (Sense): above 800 Ohm

- Display Connector Supply Pins: 250~500 Ohm

- Display Connector Signal Pins: 500~800 Ohm

- Camera Connector Supply Pins: 250~500 Ohm

- Camera Connector Signal Pins: 600~900 Ohm

- Charger Connector Tip: 600~700 Ohm

- Vibrator Motor Connector: 40~500 Ohm

- Power ON / OFF Switch Point (+): above 800 Ohm

- MIC Connector Tip (Analog MIC) (+,-): 600~900 Ohm

- Battery Charging Out Point (+,-): 300~400 Ohm

- SIM Card Connector Pin 1 (VSim): 500~700 Ohm

- SIM Card Connector Pin 2,3,6: 400~800 Ohm

- SIM Card Connector Pin 4 (GND): 00 (Beep)

- Micro SD Card Connector Pin 4: 500~600 Ohm

- Micro Card Connector Pin 6 (GND): 00 (Beep)

- Micro Card Connector Pin 1,2,3,5,7,8: 600~800 Ohm

Note: The readings given above are approximate values that may vary from device to device. The value has been arrived at based on testing of the maximum handset, you may experience some exceptions in Chinese handsets.

Troubleshooting Steps in Mobile Repairing

Testing of Components on PCB Board:

Testing Components on PCB boards with multimeters is important in the Fault Finding of Mobile Phones. In this testing method, SMD components like Resistor, Capacitor, Diode, and Coil are tested for fault.

While Testing these components, one should keep in mind that the Red Probe of the multimeter should be placed on the ground and the Black probe of the multimeter will be the testing point.

Generally, 99% of capacitor & 70% of Diode would be in parallel connection. Likewise, 99% of Coil and 95% of Resistor would be in Series connection. Most of the PCB board would be configured in the above ratio.

During testing, It is very important to know whether the SMD component is connected in Parallel or Series.

During testing (Red probe on the ground and black probe as testing lead) of components connected in a series circuit, the multimeter will give a value above 250 ohms on both sides of the SMD component (Coil, Resistor).

Likewise, for Parallel Circuit, the multimeter will give a value above 250 ohms on one side and would get beep sound (ground) on the other side of the SMD Component (Capacitor).

If you get a beep sound (ground) on both sides of the component, then check all the components in the particular section and then remove each component and check for short.

Note: If you get a value less than 200 ohms, the entire SMD component in the particular section needs to be checked.

Troubleshooting Steps in Mobile Repairing | Hot Testing Method

Hot Testing Method:

The Hot testing method is adopted when the fault cannot be found or when the cell phone cannot be repaired using the cold testing method. In this method, the VOLTAGE of the damaged part or component is checked.

The fault is found by powering the mobile phone with a battery or with the DC power supply. Once you power the phone, you should connect the BLACK probe of the Multimeter to the ground of the phone’s PCB and ensure the RED Probe touches the Testing Points.

During the hot testing method, the voltage of different part or sections should be as follows (all values in Volt):

- Earphone Connector Tip (+ , -) during working: 0 to 2.5V

- Loud Speaker / Ringer Connector Tip (+,-) during working: 0 to 2.5V

- Battery Connector Tip (+): 2.8 to 4V

- Display Connector Supply Pins: 1.8V to 2.9V

- Display Connector Signal Pins During Working: 0 to 1.8V

- Camera Connector Supply Pins: 1.8V to 2.9V

- Camera Connector Signal Pins During Working: 0 to 1.8V

- Key Tip (Row and Column) One Side: 1.8V to 2.8V

- Charger Connector Tip: 5V to 6V

- Vibrator Motor Connector Tip During Working: 1.9V to 3.6V

- Power ON / OFF Switch Point (+): 2.5V to 3.6V

- MIC Connector Tip (Analog MIC) (+,-): 1.8V to 3.0V

- Battery Charging Out Point (+,-): 3.5V to 4.2V

- SIM Card Connector Pin 1 (VSim) When SIM Connected: 1.8V to 3.0V

- SIM Card Connector Pin 2,3,6 During Working: 0 to 2.8V

- Micro SD Card Connector Pin: 2.8V

- Micro Card Connector Pin 1,2,3,5,7,8: 0 to 2.8V

Troubleshooting Steps in Mobile Repairing

Diagnosing the Problem using DC Power Supply:

Adjust the voltage of the DC Power Supply to 4.2. Place the Red Probe / Test Lead of the DC Power Supply to the “+” of the Battery Connector of the mobile phone and the Black Probe / Test Lead to “–“:

- If DC Amp is fluctuating between .15 to .75 Amp & moving to Zero once the power on button is left, then it could be a Power IC Problem.

- If DC Amp is fluctuating between .10 to .20 Amp & moving to Zero once the power on button is left, then it could be a software issue. Reboot/flashing may resolve the issue, if not check Power IC / CPU.

- If there is no movement of the Ampere Needle of the Power Supply, then the Battery connector, On / OFF Switch Track, RTC, or Network Crystal is damaged. Give heat to these components using a hot air blower. If the problem is not solved then check by replacing them one by one.

- If the Ampere Needle fluctuates below 2 then there could be problems with software or RTC (Real Time Clock).

- If the Ampere needle stands at some fixed point then there is a problem with the Flash IC.

- If there is a beep sound from the DC Power Supply then there is a problem with “+” and “–” or the mobile handset is short.

Note: When checking a faulty mobile phone with a DC Power supply, connect the Red Probe to “+” and Black Probe to “–” of the Battery Connector of the Mobile Phone.

Next, we are going to see Half Shorting / Full Shorting which is the most important Section in Troubleshooting Steps in Mobile Repairing.

Half Shorting and Full Shorting

What is Half Short and Full Short in Mobile Phone PCB?

Half Short | Half Shorting:

Half Short or Half Shorting of a Mobile Phone PCB is the Condition when a Phone Gets Switch ON and it also works but the Battery Drain Very Fast. This means that there is some dry solder on the PCB of the Phone or some small Component such as an SMD Capacitor is Faulty/Short which needs to be Removed / Replaced.

How to Check Half Shorting:

- Keep the Digital Multimeter in BUZZER Mode.

- Check the Battery Connector of the Phone in Forward (Red Probe on Positive and Black Probe on Negative). If the Value on the Multimeter is 1 then the PCB is OK and there is NO Shorting.

- Now Check the Battery Connector in Reverse (Red Probe on Negative and Black Probe on Positive). If the Value on the Multimeter is Between 250 to 600 there is NO Shorting and the PCB is OK.

- If Value arrives at Both Forward and Reverse Checking, then there is Half Short.

Full Short / Full Shorting:

Full Short or Full Shorting of a Mobile Phone PCB is the Condition when a Phone does NOT get Switch ON and the Phone is Dead. This means that one or more than 1 of some Major Electronic Components is Faulty and the Board needs to be checked thoroughly to Fix the Problem.

How to Check Full Shorting:

- If there is BEEP Sound in Both Forward and Reverse bias then there is a Full Short.

- If we connect Positive (+) and Negative (–) of the Battery Connector to a DC Power Supply Machine, Ampere (A) would Starts to Decrease without Switching ON the Phone, Then there is Full Shorting in the PCB of the Phone.

The Solution to Fix Shorting in Mobile Phone

- To Fix Half Shorting, The First Step is to Disassemble the Phone and Clean the PCB Thoroughly with IPA Solution and the Apply Heat All over the Board using Hot Air Blower Machine.

- Assembly Back the Phone and Check if the Problem is Solved or Not.

- In Most Cases, the Problem gets Solved. But if there is still Half Shorting then Check for Tiny SMD Capacitors Near the Battery Connector. Remove the Faulty One.

- In the case of Full Shorting, Connect the Positive (+) and Negative (–) of the Battery Connector to a DC Power Supply Machine. Amp will Start to Decrease without Switching ON the Phone.

- This means there is Full Shorting in the PCB of the Phone. In this case, connect positive and negative of DC power supply to the battery connector, then reduce the voltage to zero and then increase the voltage slowly to the cut off point where Ampere starts to decrease. Keep at that point for a few seconds and check if any component is getting heated. You can feel the Heat of the Faulty Component with your Fingers. If any component gets heated then it needs to be checked and Replaced.

These are the general Troubleshooting Steps in Mobile Repairing.