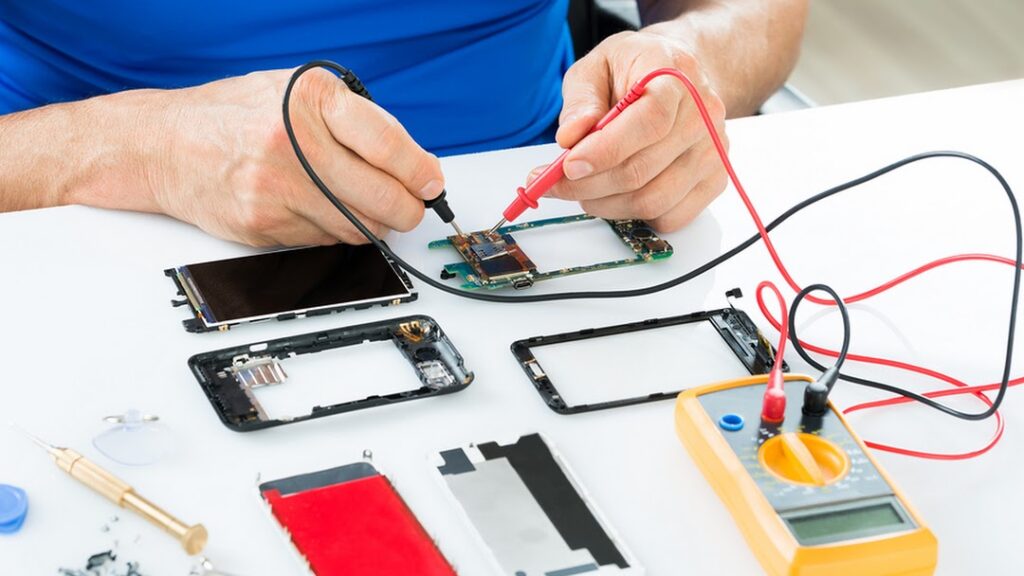

Fault Finding of Mobile Components is a very important lesson in Mobile Repairing. One Should know how to check & diagnose the problem arising due to faulty mobile components.

Fault Find of Mobile Components

The major electronic components in the mobile circuit are Capacitor, Coil, Resistor, Diode & IC’s. It is very important to know how these components are working & what kind of issues arises if these components are fault.

One of the main components often gets fault is the capacitor as it is easily prone to get damaged or fault which leads to Half shorting or Full Shorting.

Almost 50% to 60% of fault in the mobile circuit would be due to leaking or shorting of the capacitor.

Let us see the fault finding of mobile components one by one.

Capacitor

To check the fault of the SMD Capacitor, first keep the multimeter on Buzzer mode. If it is good, then the multimeter will not give any Beep or Buzz sound.

If there is sound or any value then the capacitor is faulty which needs to be replaced with a new one.

It is very important to note that 98% of the capacitor would be in Parallel Connection. While checking it directly on the motherboard, One side should show a value above 250 ohms & the other side should get a beep sound. During this cold testing, the Red Probe of the multimeter to be connected to the ground & the black probe would be the testing point.

If get a beep sound on both side, then the capacitor might be faulty. In this case, you need to check all capacitors, diode around the section for a fault which needs to be check & replace one by one.

Inductor or Coil

To check SMD Coil, first keep the multimeter in Buzzer mode.

If it is good, then the multimeter will give a Beep or Buzz sound. If there is no sound then the coil is faulty which needs to be replaced with the new one.

While checking the boost coil, it should show values from 2.5 ohms to 10 ohms. If it is not within the range, then the boost coil needs to be replaced.

Resistor

To check SMD Resistor, first keep the multimeter in Buzzer mode.

If it is good, then the multimeter will give a Beep or Buzz sound. If there is no sound, then keep the multimeter in ohms mode & check if the resistor is showing any high value above 2K.

If it showing value, then the resistor is good, or else it is open which needs to be replaced.

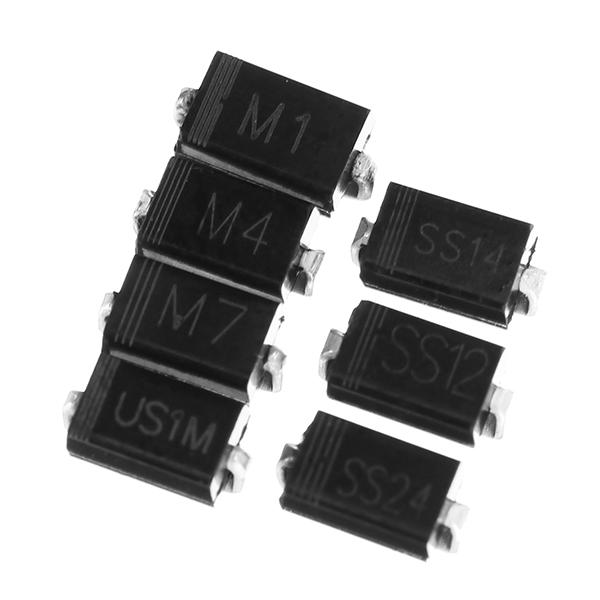

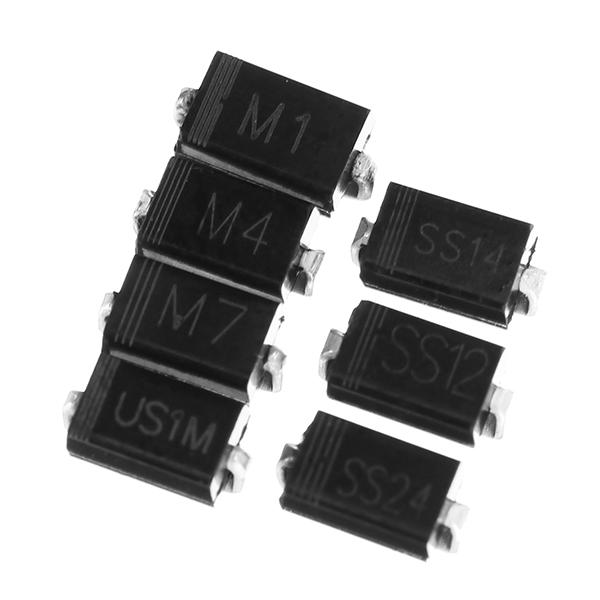

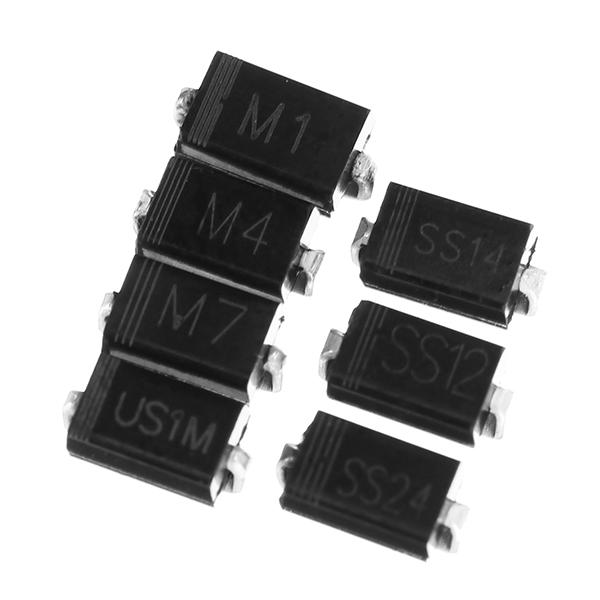

Diode

To check SMD Diode, first keep the multimeter in Buzzer mode.

Connect positive of the multimeter probe to Anode (+ve) & negative of the multimeter probe to cathode (-ve) which is said to be forward bias. In this condition, the multimeter should show a value between 130 to 600 ohms.

Then place the multimeter probe in the reverse direction (reverse bias)., i.e., positive probe to cathode & negative probe to anode. In this condition, the multimeter should not give any value.

If there is sound or both side value, then it needs to be replaced with a new one.

Note: There is no polarity for SMD Capacitor, Resistor, Coil. It can be removed or place in any direction. But Diode has a polarity which needs to be replaced with the new one in the same direction. You can find one vertical mark near the cathode point.

These are the important process of the Fault Finding of Components in Mobile Repairing.